Choosing the right ramp for loading vehicles or machinery can be a painstaking process. There are so many variables at work. You’ll want somethins safe, sturdy, and does the job quickly. And something that won’t damage the vehicle you’re loading.

Things to Look for in a Ramp

The first consideration is the type of vehicle that the ramp needs to support. Here there are specialised ramps, ranging from those that do better with motorbikes, ATVs or light farm and industrial machinery, to heavy-duty ramps intended for cars, trucks, and heavier warehousing, construction, and other equipment. The weight a ramp can take will vary widely between different models, as will the designs in terms of overall width, length, and the type of loading surfaces they come in.

Weight Capacity

If you’re looking for heavy-duty car ramps, or ramps used to load rubber tracked vehicles, weight capacities generally start at around 2 tonnes and go on to 15 tonnes for heavier vehicles and machinery. What’s important is to know the weight of the vehicle you’re loading, including fuel, oil and any additions. In addition, there’s the driver or operator weight to consider. One of the biggest mistakes is loading cars, utes, excavators, or loaders on ramps that aren’t rated to do so. You might make it on the trailer or truck, and then again, chances are you might not. And that’s going to be one expensive repair bill you want to avoid at all costs. For channel ramps (these are the most sold on the market), capacities are often stated as the combined loading weight of the ramp pair.

Width and Length

Widths are stated as inner and outer widths. Inner widths are up to the ramp sidewalls or beams, whereas outer widths are with the sidewalls included. You’ll want a car ramp that can comfortably accommodate the width of the car tyres, with a few centimetres to spare on either side for leverage. Most ramps hover around 300mm inner width, but extra wide ramps, in 450mm or more, will come in handy when loading 4WDs or ATVs with larger off-road tyres as well as bigger tracked machinery.

Lengths vary. Generally, a longer ramp is better for vehicles with lower ground clearance. Think performance cars or restored old-timers. Here longer car ramps provide adequate loading angles so you don’t damage the rocker panels and sills when getting the car onto the ramp. Most ramps for cars are around 3 metres, but those with higher weight capacities are often longer (and wider), with some extra heavy-duty variants measuring 5 metres or more.

Ramp Surfaces

The rungs in car ramps need to be spaced evenly to support the weight of the vehicle. What is more important though is that they are designed to offer the right amount of traction. This avoids slippage when loading and unloading your vehicle. Flat, or lightly textured rungs have enough grip without damaging tyres. Rungs on ramps for rubber-tracked construction and industrial machinery may have more pronounced perforations.

These are not to be used with machinery running steel tracks. To avoid damage, rungs intended for use with steel tracked machinery and vehicles, often have milled surfaces set in a triangular shape. These can also be used for cars and vehicles with rubber tracks.

Stability and Safety

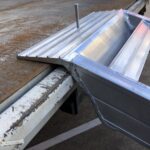

How the ramp connects to the loading vehicle or trailer affects stability when getting the car on or off. Here ramp ends are designed differently. Look for ramps with an integrated hook to lock it into place with the truck or trailer. Some of these have extended bars or plates for further stability.

More secure are ramps with connecting plates and pins. The pin secures the ramp to the vehicle and ensures it will stay put no matter what.

Ramp Feet

How the ramp sits on the ground also matters. The feet are the part of the ramp that is in direct contact with the ground. Here too there are different designs, and some perform better with different vehicles. For heavier vehicles, and those with higher ground clearance, ramps with stub feet provide a solid loading base with a pronounced bump. For cars sitting lower, a better idea Is to have a ramp with tapered knife-cut feet, as these provide a smoother transition between road and ramp.

Materials

Ramps for cars need to be sturdy, durable, and lightweight. Aluminium ticks all the boxes and aluminium ramps are by far the most common. For durability, ramps with higher loading capacities will also be reinforced with bottom brackets in multiple sections. In terms of weight, most are light enough to be carried, set, and removed by a single person. For instance, a standard 2500mm car ramp with a 2-tonne capacity, weighs a manageable 20 kilos per channel. Longer and wider ramps for bobcats and excavators are almost triple that at around 55 kilos.

Which Car Ramp to Buy?

This depends on the type of car you’ll be using the ramp for. Consider the car’s ground clearance and overall wheelbase in getting the right length. Here too, the height to which the car will be loaded also has a say. To provide for safe loading angles when loading the car onto higher trailers or trucks, get a longer ramp. Option a ramp that is also wide enough, with a bit of breathing space on either side of the tyres.

In addition, consider the weight of the car, or the tracked vehicles with attachments included to get a ramp with the right weight capacity. Pay attention to the rung types and designs for optimal grip. Lastly consider how the ramp attaches to the trailer or truck, and how it sits on the road.

With all things right, loading and unloading cars should be safe, simple, and quick every time.