If you’re reading this, chances are you are someone who loves the sound of custom exhaust systems or you just want more from your D40 Navara exhaust. Aftermarket exhaust systems have become all the rage lately, and for all the right reasons. Car manufacturers are trying to cut costs left and right in order to make their vehicles more competitive in today’s oversaturated market, and one area where shortcuts are taken is the exhaust system. This doesn’t mean that your Navara’s system is bad, but it could definitely be much better. Aftermarket exhaust systems are the most affordable upgrade you can get to significantly improve how your vehicle performs and how much fuel it spends.

So what do you need to look for when choosing an aftermarket D40 Navara exhaust? Well, there are quite a few factors that make or break the performance of exhaust systems, the most important ones being:

Materials It’s Made of

Stock exhaust systems are made using mild steel. While mild steel is a decent material for exhaust manufacturing, it’s not ideal. Aftermarket exhaust systems, on the other hand, are made using either aluminised or stainless steel. Both of these materials are superior to mild steel in terms of durability, heat-, corrosion-, rust- and humidity-resistance. Stainless steel is the stronger option out of the two, but it’s also heavier, meaning it can actually hurt your Navara’s mileage. Stainless steel exhaust systems are recommended for off-roaders and people living in coastal area where the humidity is high. Aluminised steel aftermarket exhaust systems are lighter in weight but also more expensive. While they’re not as strong as stainless steel, they are often powder coated to improve their durability and resistance properties.

Clearance and Fit

No matter whether you go for an aluminised or stainless steel exhaust, you have to make sure the system you choose fits your vehicle. A wide range of aftermarket exhaust systems are designed to fit specific models and makes, but there are also universal models as well. The reason why most people opt for vehicle model and make specific exhaust systems is to ensure an easy fit without having to perform heavy modifications to your vehicles. There’s also the option of having the exhaust system tailor-made not just for your vehicle make and model, but the type of application you need it for. You should choose the pipe and part diameter based on the size of your engine. Generally, a performance V8 engine requires a pipe diameter of 2.5 to 3.5 inches. But keep in mind that pipe diameter can vary based on the application and the type of system (single exhaust systems require larger pipes than dual exhaust systems).

Bending Technique

The way the pipes are bent in the manufacturing process can play a crucial role in how efficiently air flows through the entire exhaust system. There are three types of bending – crush, wrinkle and mandrel.

Crush bending is also known as press or compression bending, and it refers to tube bending where only a die and backing shoes are used. Although you get functional bends, the pipe is bent on the inside of the radius, leaving a depression alongside it. This is the most economical and readily available bending technique, which is why most car manufacturers use it.

Wrinkle bending is also known as crinkle bending. Wrinkle bending is achieved with the help of heat. Heat is applied until the pipe is red-hot, and the pipe is forced along the die. The inside throat of the bend collapses in a series of wrinkles. While superior to crush bending, wrinkle bending still reduces the inside diameter and creates a series of humps that can negatively impact flow and sound.

Mandrel bending is a technique that’s quite similar to crush bending, except there’s also a mandrel used in the process on top of the backing shoes and die. The mandrel supports the inner walls of the pipe as the pipe is pulled through the die and backing shoes. As a result, you get smooth, virtually uninterrupted pipe diameter. The mandrel is lubricated with lithium grease to provide a smoother gliding action inside the pipe.

Parts the Aftermarket System Includes/Replaces

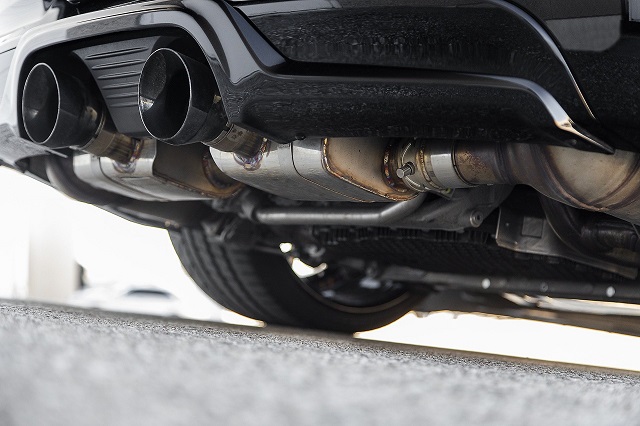

Exhaust systems are made up of a few key parts, including exhaust headers, a catalytic converter, resonator, muffler and pipes.

The exhaust headers are the first point of contact for the exhaust gases when they leave the cylinder head. Exhaust headers are the most commonly replaced exhaust parts, simply because aftermarket headers feature wider diameters. As a result, you get improved scavenging by aligning the pulses in a more favourable manner.

The catalytic converter is responsible for cleaning the toxic gases coming out of the headers into less-toxic gases before releasing them into the atmosphere. Driving a vehicle without a catalytic converter is illegal in most of the world. For that reason, make sure the aftermarket system you’re considering has a catalytic converter.

The resonator is not part of the exhaust system, but it’s often included to reduce noise. The muffler is also responsible for reducing noise, but there are some aftermarket exhaust systems that feature mufflers which actually make your vehicle sound more aggressive.