The vibratory plate compactor is a very useful piece of compaction equipment used for many different construction jobs such as road construction, construction of parking lots, sidewalks, patios, etc. The usage of these construction machines at construction sites requires some safety procedures to be followed in order to avoid accidents and injuries. In fact, safety is the primary concern when it comes to the design of this compaction equipment. Manufacturers are very detailed oriented when it comes to safety all in order to ensure 100% protection. However, regardless of the brand, the safe operation of the vibratory plate compactor or any other piece of compaction equipment, depends on the user. The following text is a simple and easy-to-understand guide on the safety rules that need to be followed when operating a vibrating plate compactor.

The very first thing that requires close attention is the proper selection of the the right compaction machine for the job. Many different models are available on the market and are generally classified by their size, power, weight, type and model. Each type has its own advantages and disadvantages and it is designed for a particular compaction task. The operator needs to be aware of the unique characteristics and limitations of each compaction machine in order to use the right one.

The rammers, or also known as Jumping Jacks, are designed with a percussive compaction system and show the best results when used for compacting small and confined areas.

The rammers, or also known as Jumping Jacks, are designed with a percussive compaction system and show the best results when used for compacting small and confined areas.

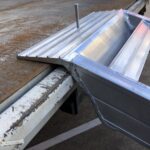

- Vibrating plate compactor is an excellent machine that can be used for compacting larger areas when compared with the Jumping Jacks. The reversible vibrating plate compactor has the capability to move not only forward but also in reverse.

- Walk behind smooth drum rollers can be used for either soil or asphalt compaction.

- Trench rollers feature sheep foot style rollers and can be used for achieving high compaction results in trenches. These machines generally are operated by a remote control but can also be operated manually by the user.

The manufacturers of vibratory plate compactor incorporate many different safety features in the design of this compaction machines. Every vibratory plate compactor operator must be well informed about the safety features in order to maximize the protection and increase the performance and productivity of the compactor. Some vibrating plate compactors may include protective cushions, reinforced plate at the bottom of the machine and triple resistant vibratory design. These safety features provide increased compaction performance. Depending on the brand, model, size and application, selected compactor may include these and many other safety features.

Safety should always be operator’s main priority when using the vibratory plate compactor. Before starting any construction or compaction task, the operator needs to understand and to follow several safety rules in order to increase the protection and to maximize the performance of the machine.