Loading heavy and bulky items on and off vans, utes and trailers can be a daunting task. You risk injuries, damaging items and equipment and losing valuable time and effort that can be put to better use elsewhere. Ramps might not get the wow factor they deserve, but they’re an essential component when moving machinery, vehicles and equipment in numerous industries, from transportation to construction. With that said, not all ramps are created equally. You’ll want a durable and well-built ramp rated for the equipment and one that is safe and stable, yet lightweight to make frequent loading and unloading a breeze.

Benefits and Uses of a Heavy-Duty Loading Ramp

Despite the straightforward and unassuming design, heavy-duty trailer ramps have simplified wheeling cars, motorcycles and ATVs onto trailers, trucks and vans. This can be dirt bikes sitting on bike stands, your prized classic car, and trucks and vehicles in need of repairs. Every ramp is designed for fast and tool-free setup, meaning less time loading and unloading and more to deliver vehicles where they’re needed.

Part of this functionality is down to the durable designs, with high-grade steel or aluminium easily capable of supporting thousands of kilos worth of gear. Each ramp includes supportive beams and reinforced rungs to allow for equal weight distribution and prevent pressure points and buckling, even under the heaviest loads. The quality materials, clean welds and high loading capacities deliver peace of mind and reliability for demanding loading and unloading tasks regardless of the setting or equipment.

This kind of durability and versatility extends beyond personal uses, with loading ramps regularly seen in the agricultural sector when moving harvesters, tractors and other farming equipment. And in warehouses and construction sites, where they’re frequently used to transport forklifts, loaders, stackers, order pickers, tractors and other equipment. The larger layouts also simplify getting construction materials like bricks, concrete block, plasterboard and timber onto flatbed trailers or truck beds.

Choosing the Right Ramp for Your Needs

With so many variables, choosing the right ramp can be a time-consuming task. You’ll want something safe and reliable, easy to setup and use, and that makes regular loading and unloading tasks efficient and straightforward. Here’s a breakdown of the most important factors to consider when buying trailer ramps:

Loading Capacity

Correct weight loadings ensure safety. Calculate the total weight of the equipment, including that of operators and connected accessories and leave some margin for peace of mind. Also, ensure that combined ratings of separate channel ramps can safely support any equipment or machinery. Smaller types can handle up to 1.5 tons per channel when loading cars and lighter vehicles. For industrial and agricultural machinery you’re better off with the higher weight loadings of larger, wider and better-built heavy-duty options, some capable of supporting 6000 kilos or more.

Length and Loading Heights

Lengths also impact safe loading angles. Generally, longer ramps can safely ease in heavier equipment by minimising the risk of equipment and machinery stalling, slipping or tipping over. This also means safer and faster operation with trailers and vehicles with higher loading lips. Check lengths of ramps before buying, with common ranges between 1.8m in smaller versions and up to 3.5 metres in ramps used with construction, warehousing and other heavy equipment.

Materials and Designs

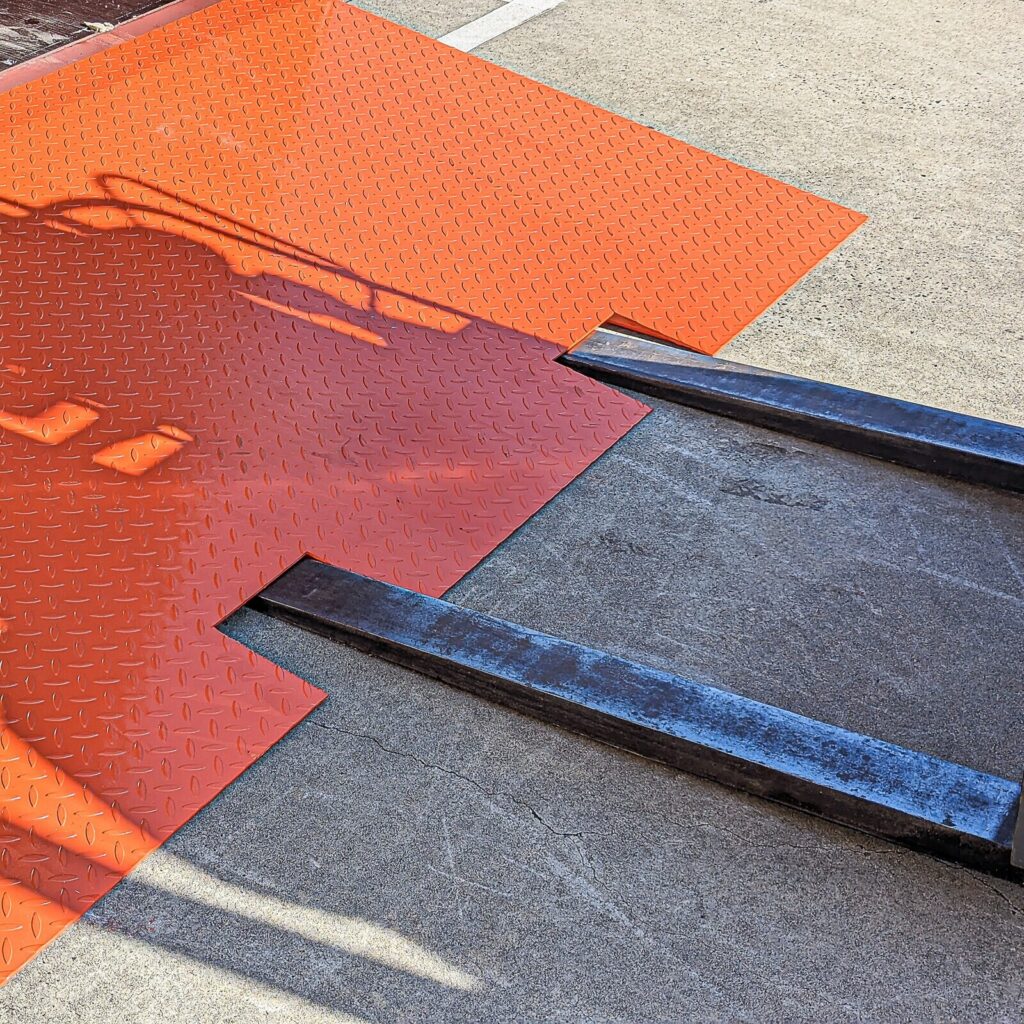

Choose aluminium for light weight and portability, or steel ramps for heavy-duty applications. Aluminium is rust-free, retains looks for longer and is easier to clean. Steel ramps need to be surface-treated to prevent corrosion and staining, but are preferred when loading heavier items. To ensure maximum safety, also look at design specifics in rungs and tracks. Non-slip inserts and textured surfaces for instance increase grip, while angled rungs secure the track plates in machinery like bobcats and excavators for faster and safer operation.

Ensure that the ramp also includes raised sidewalls for increased stability and to prevent tipping over, adequate drainage to wick away water and debris, and is capable of performing in multiple settings and different weather conditions.

Portability

If you use ramps daily, lower weight and portability make transporting vehicles and equipment much easier. While heavy-duty ramps often miss out on folding options due to load capacity restrictions, most round out to 30 kilos or less, so can easily be moved and set up by one person. And to take up less space when stored, consider niceties like straps. These also keep ramps secure when travelling atop trailer and truck beds.

Safety Features

Provided connecting plates, pins, hooks and chains ensure that the ramp stays put during loading or unloading. This works well with the anti-slip and textured surfaces, the raised sidewalls and additions like visual safety markings or load guides that combined, all increase safety. Needless to say, inspect ramps for damage or wear before use and follow all safety precautions and protocols when loading and unloading gear.

Your last consideration is compatibility with your trailer or truck, in terms of widths and loading heights, how and where it will be stored when not in use, and whether it offers the adaptability to be used with other trailers and hauling vehicles.