Technological advancements have greatly improved the capabilities of 3D printing and its implementation in various industries. Thanks to the continuous development of new and improved printing materials, designers and engineers now have more options to choose from to create prototypes or end-use products with desired properties.

One such material that delivers consistently accurate results is wear-resistant ASA 3D printing filament. It shares many properties with ABS filament but with improved weather resistance and UV stability.

What Is ASA Filament?

In short, ASA (Acrylonitrile Styrene Acrylate) filament is a thermoplastic polymer that offers excellent mechanical strength, durability, and thermal resistance. It is often used as an alternative to ABS filament because it can withstand harsh outdoor conditions better.

It’s produced by polymerizing acrylonitrile, styrene, and polybutadiene. The combination of these polymers results in a material with improved thermal stability, chemical resistance, and impact strength.

While it does share some properties with ABS filament, ASA is known for its exceptional resistance to UV light and harsh weather conditions. This makes it a popular choice for outdoor applications and functional prototypes that require long-term durability.

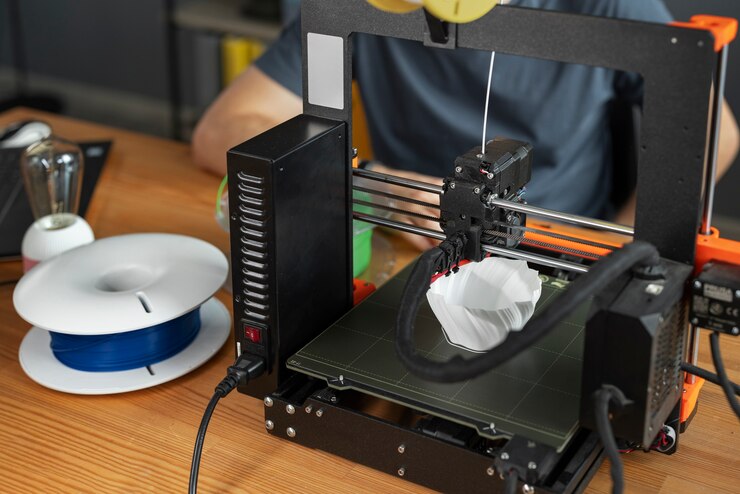

An Overview of the Printing Process

ASA 3D printing filament can be printed on most desktop FDM 3D printers with a heated bed. It has a printing temperature range of 230-260°C and requires a heated bed temperature of 80-110°C. Like ABS, it’s prone to warping, so using a good adhesion method, such as a brim or rafts, is crucial for successful prints.

One major difference between ASA and ABS filaments is the cooling process. ASA requires slower cooling compared to ABS, with some printers even having specific settings for printing with ASA. This allows the layers to cool down more gradually, reducing the risk of warping or cracking.

Benefits of Using ASA Filaments

Thanks to its multi-functional properties, ASA filament has many benefits over other thermoplastics. Some of these include:

Excellent Weather Resistance

ASA has excellent resistance to UV light, which means it can withstand outdoor conditions without significant discolouration or degradation. This makes ASA a popular choice for 3D printing functional and durable outdoor objects, such as garden furniture, signage, and automotive parts.

For instance, if you want to print a personalized mailbox for your home, using ASA filament will ensure that it maintains its color and structural integrity even after prolonged exposure to sunlight and harsh weather conditions.

Improved Chemical Resistance

ASA is also highly resistant to chemicals, making it suitable for industrial applications where the printed object may come into contact with harsh chemicals. This includes chemical storage containers, laboratory equipment, and chemical-resistant components in machinery.

Let’s say you need to print a custom chemical-resistant part for your laboratory experiment. Using ASA filament will ensure that the printed object can withstand exposure to various chemicals without degrading or reacting.

High Impact Strength

ASA has high impact strength, meaning it can resist sudden impacts and heavy loads without cracking or breaking easily. This makes ASA ideal for printing functional parts that may experience high stress or strain, such as tools, gears, and mechanical components.

For example, if you’re designing a new tool for automotive repair, using ASA filament will ensure that the tool is strong enough to withstand repeated use and potential impacts without breaking.

Versatility

One of the greatest benefits of using ASA filaments is its versatility. It can be used for a wide range of applications, from functional parts to decorative objects. ASA filament is available in a variety of colours and finishes, making it suitable for creating visually appealing prints.

For instance, if you want to add a pop of colour to your 3D-printed phone case, using ASA filament will allow you to choose from a range of vibrant hues without sacrificing durability or quality.

In addition, ASA can also be easily post-processed with sanding, painting, and even acetone vapour smoothing techniques. This allows for even more customization and fine-tuning of the final print.

Potential Challenges When Using ASA Filaments

Despite its many benefits, there are some potential challenges to keep in mind when using ASA filaments. One of the main challenges is its sensitivity to high temperatures.

It has a higher printing temperature compared to other popular 3D printing materials like PLA and ABS. This means that you will need a 3D printer with more advanced heating capabilities to successfully print with ASA.

In addition, it also has a higher tendency to warp or shrink during printing, especially when printing larger objects. This can result in warping and distortion of the final print if not properly addressed.

To avoid these challenges, it is important to ensure that your 3D printer has proper temperature control and an enclosed build chamber to maintain consistent heat levels throughout the printing process. It may also be helpful to use a heated bed and adhesion aids like glue sticks or hairspray to prevent warping and promote bed adhesion.

Even if you encounter challenges while printing with ASA filaments, don’t be discouraged. With some trial and error and proper printer settings, you can achieve high-quality prints with this versatile material.

Read the manufacturer’s guidelines and experiment with different settings to find the best temperature, print speed and cooling settings for your specific printer and products.