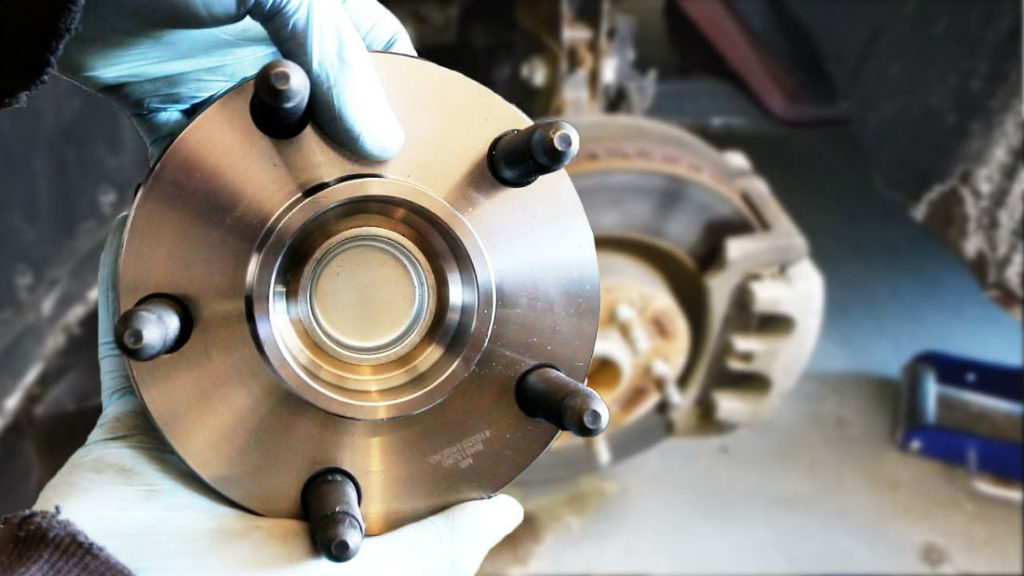

The performance and durability of your vehicle depends on the parts inside it. This includes the chassis, the engine and the exhaust system, but there is another part your vehicle just won’t be able to operate without as well. I am talking about the wheel bearing or hub, and although this part is not a very popular component, it plays a major role when it comes to performance and safety. Basically a wheel hub is the mechanism that helps the wheel revolve and without it, handling your vehicle would be like riding a bike in the mud. Nowadays there’s a lot to it than just making driving easier.

What to Look For

Compatibility

There are a lot of options when it comes to vehicle parts but with wheel bearings, the options equal the number of different vehicles available on the market. The wheel hubs should match dimensions and not what model or make your vehicle is as different models make use of the same bearings as they have the same size wheels. You should still check the manufacturer’s spec sheet though, to make sure you get the product that will work best with your vehicle.

Material

The quality of the material will depend on the type of steel construction the bearing is made of – yes, steel is the only option here, but it comes with different coatings. These are called steel grades and each has a different level of durability with the more expensive ones being the more durable options. Before purchasing, it’s important that you check the type of steel your bearings are made of so you know how they behave in temperature changes – this will tell you if you need to do an upgrade or not.

Manufacturer

Sourcing your new wheel hubs is the best way to replace them or get them fixed as the manufacturer usually has important details. Knowing the origin of your wheel bearings will tell you how well the product performs and in some cases, you’ll find out that the bearings don’t comply with foreign or domestic vehicles which is good to know beforehand.

Pricepoint

If you want to get the best wheel hubs you can afford, it is going to take spending some time comparing various products price and specs wise too. This helps you identify what exactly you need and can prevent you from spending on features that sound cool but don’t benefit you.

Types

Ball Bearings

These are the most commonly used bearings and not only are they used in car wheels but they are also used with roller skates which is mainly due to their versatility and affordability.

Precision-Ball

An upgraded version form regular ball-bearings, these are made to work very well under pressure which is why they are sued in racing cars and in aeroplanes too since they have low heat dissipation and high rotation speed.

Roller Bearings

Although these types are not used in vehicles, they have found a place to show their capabilities – in hand trucks and grocery carts, as they are very good at handling radial loads.

Common Issues

Excessive Wear

This is usually seen on the cone bore in the form of discoloured ridges and signs of damage due to heat which comes as a result of cone turning. The cause of this is usually the loss of axle retention or the reinstalling of a worn-out hub which makes the inner race spin on it thus the accelerating wear on the hub barrel and cone bore. An improper fit and a loss of bearing can be the cause of the cone turning. The solution is simple, if you notice any discoloured ridges and visible damage on the barrel of the hub replace it as soon as possible.

ABS Malfunction

The Anti-lock Braking System may have a pinched cable or a broken wheel speed sensor preventing it from working properly which usually shows up as the system being on when it shouldn’t be. Damage from sharp objects, cracks on the external sensor and a loose cable into the sensor head can all lead to the malfunctioning of the ABS system with the most common cause being a damaged sensor cable. The best way to determine the exact cause and the solution to it is through inspection, so make sure the sensor cable is going through all retainer clips in order to avoid a pinched cable. Hubs can also affect the state of the system if they aren’t in good condition.

Loss of Bearing Retention

The cause of wheel vibration and excessive noise coming from the wheel hubs in the form of clicking, snapping and propping is what you get from worn-out axle nuts, which are an indication of the loss bearing self-retention. When there is an improper torque level on the bearings, the axle nut backs off and causes accelerating wear and misalignment. This can also lead to excessive wear and in order to prevent both, you have to make sure when mounting a new hub that you use a new axle retaining nut and tighten it to the proper torque level.