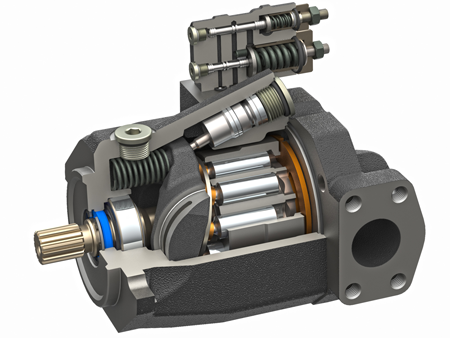

A hydraulic pump is described as extremely useful device which is designed to move different kinds of liquids with high pressure or through suction. The hydraulic pumps are capable to transfer energy, and usually are powered by some energy source that has no part in the pumping action of the hydraulic pump. A kinetic energy is created inside the hydraulic pump, which moves the liquid that is under pressure in what is known as pump outlet. Usually, a non compressible fluid, such as oil, is pushed against one small diameter piston. This small piston then causes the fluid to move through second piston which is located on the opposite side of the pump. This way the force inside the hydraulic pump is increased. Today, the hydraulic pumps are heavily used in many various applications and machines that require strength and power like dump trucks, breaking systems, construction loaders or excavators and many other industry machines.

The hydraulic pumps can be found in different sizes, shapes, power rates and flow ratings. If the cylinder of the hydraulic pump is constantly involved in raising heavy weights, then a pump with one piston or double acting pump is recommended. For some applications that involve little or no resistance but generally require high level of force, a two speed piston pump will be the most appropriate choice. For applications that need a double acting cylinder, a hydraulic pump with four-way valve is needed. For selecting the most appropriate hydraulic pump you need to know the weight of the load that is going to be lifted, the number of the cylinders and the travel length of the cylinder.

The pressure capacity is the crucial factor when searching for the right hydraulic pump. The load is what actually creates the pressure and not the pump. A rotary action inside the pump moves the fluid through the pump. The pressure rating of the hydraulic pump is determined by the ability of the pump to withstand high pressure without causing internal damages to the parts of the pump or internal leaks. Medium or low pressure pumps are ideal for simple and moderate works. On the other hand, a high pressure hydraulic pump will be needed when heavy construction equipment is used.

Today new innovative diagnostic technology has been developed that helps a lot in predicting when the hydraulic pump will fail. For this purpose a discharged pressure is measured so that the failure of the pump can be predicted, and also, this way the remaining life of the hydraulic pump is determined. This new technology replaces the vibration signal detection method which is strongly affected by the environmental interference. This new detection system can be integrated very easily into existing hydraulic pumps without any modifications.